BREWING, BOTTLING, FERMENTATION, STORAGE TANKS, EMULSIFICATION, PIPING SYSTEM, CANNING, SANITARY, CIP, PASTEURIZATION, MIXING, MEAT PROCESSING AND SMOKING OVEN, REFRIGERATION

Filters Sort results

Reset Apply

|

|

|

||

|

Temperature is a critical parameter in all systems, regardless of the process. In every heating or cooling system, variations occur throughout the medium—temperature gradients always exist. In many applications, measuring…

Find more..

|

|

||

|

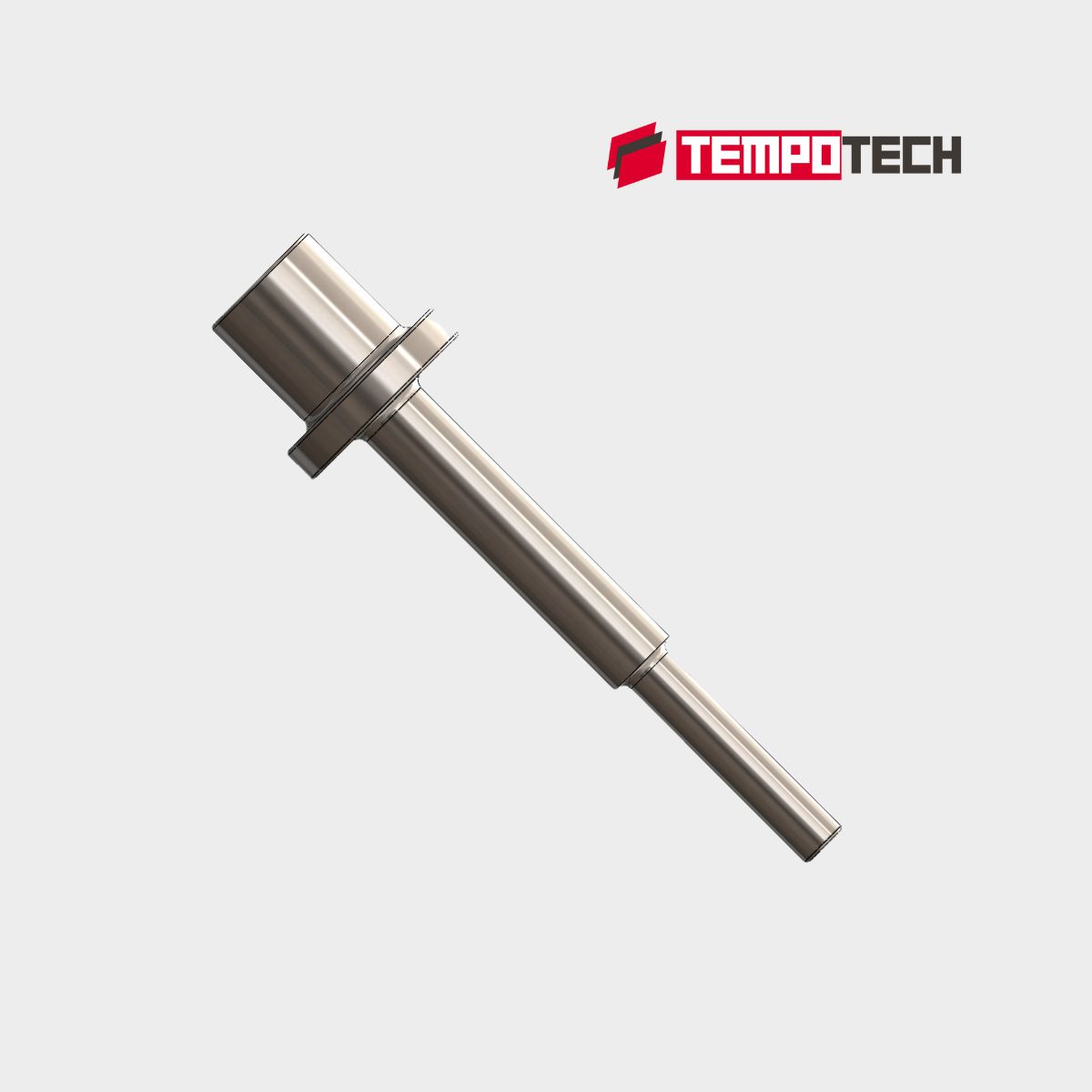

Vanstone thermowells are essential for temperature measurement applications, providing a protective barrier between the process medium and the environment. They safeguard both personnel and surroundings by preventing aggressive substances, high…

Find more..

|

|

||

|

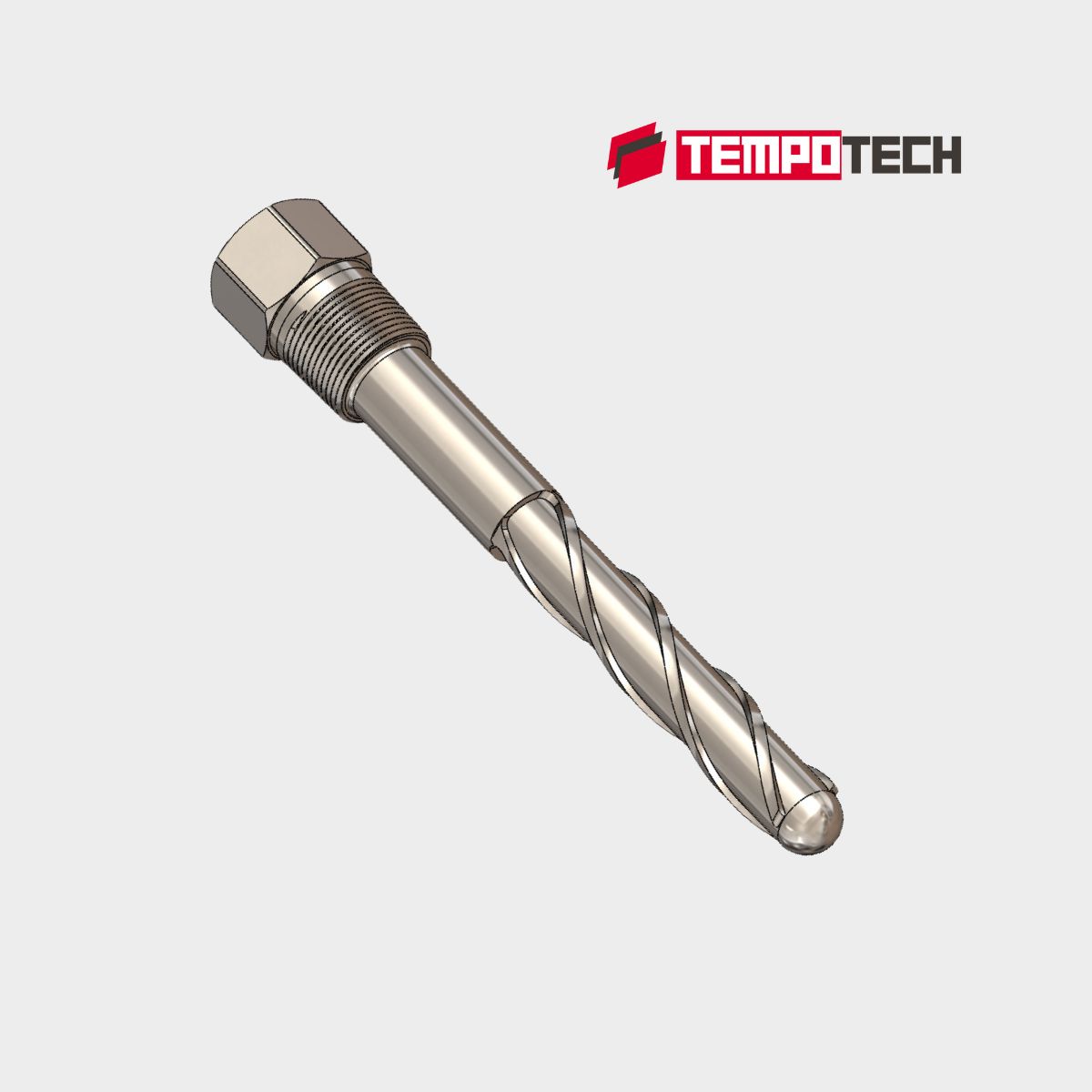

To avoid thermowell damage from mechanical loads, it is suggested performing a wake frequency calculation according to ASME PTC 19.3 TW-2016 standards for critical processes. If results are negative, solutions…

Find more..

|

|

||

|

To avoid thermowell damage from mechanical loads, it is suggested performing a wake frequency calculation according to ASME PTC 19.3 TW-2016 standards for critical processes. If results are negative, solutions…

Find more..

|

|

||

|

To avoid thermowell damage from mechanical loads, it is suggested performing a wake frequency calculation according to ASME PTC 19.3 TW-2016 standards for critical processes. If results are negative, solutions…

Find more..

|

|

||

|

|

|

||

|

|

|