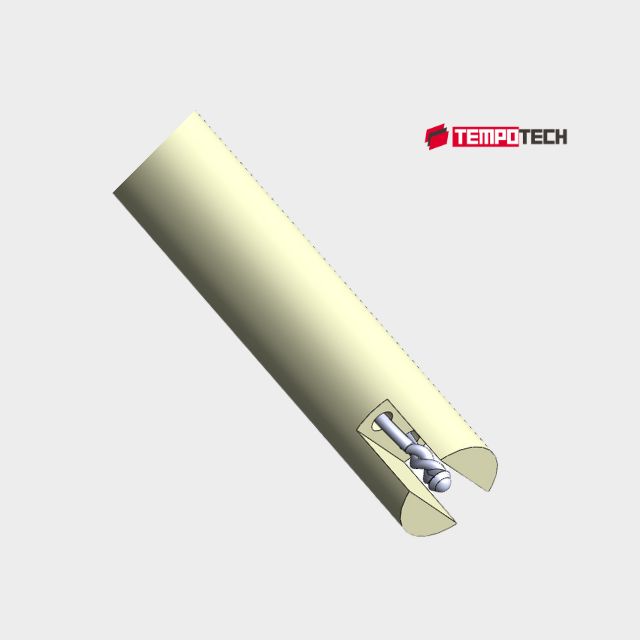

TC201- A Noble Metal Industrial Thermocouple with DUAL Protection Tube is a highly accurate temperature sensor engineered for extreme heat and demanding industrial conditions. It features noble metal thermocouple elements (Types R, S, B and C) enclosed within a protective tube, providing exceptional durability and longevity in high-temperature applications. These thermocouples are widely used in industries that require precise temperature control, stability, and resistance to oxidation and corrosion.

Key Feature:-

- Available in different thermocouple types & Temperature Ranges upto 2315°C (4200°F)

- Dual Protection Tube

- Noble metal thermocouples provide superior stability and minimal drift over time.

- Available in different protection tube materials like Ceramic (Alumina, Mullite, Silicon Carbide) for High-temperature and corrosion resistance and Metallic (Platinum, Inconel, or Stainless Steel) for added mechanical

strength and oxidation resistance - Protection tubes shield the sensing element from aggressive environments, molten metals, and gases

- Description

Application Note

High-temperature monitoring plays a crucial role across various industries that involve extreme heat processes. In power plants and refineries, it ensures safe and efficient operation of reactors and incinerators. Similarly, in steel and metal processing plants, it is essential for maintaining optimal heat levels in furnaces, foundries, and molten metal applications. The glass and ceramic manufacturing industries rely on precise temperature measurement for processes like kiln and glass melting to produce high-quality products. In heat treatment and aerospace sectors, temperature control is vital in extreme heat environments to meet material specifications. In semiconductor manufacturing, temperature monitoring is critical during chemical vapor deposition (CVD) and epitaxy processes, which are used for wafer processing and crystal growth. The need for precision continues in metal hardening and coating processes carried out in vacuum and controlled atmosphere furnaces. Additionally, high-temperature monitoring is integral in the firing and sintering processes in tiles and ceramics production. Finally, the glass industry uses temperature control to monitor molten glass, ensuring that the melting and forming processes result in high-quality glass products. Across all these applications, maintaining accurate temperature levels is essential to ensure product quality, safety, and efficiency in high-temperature operations.