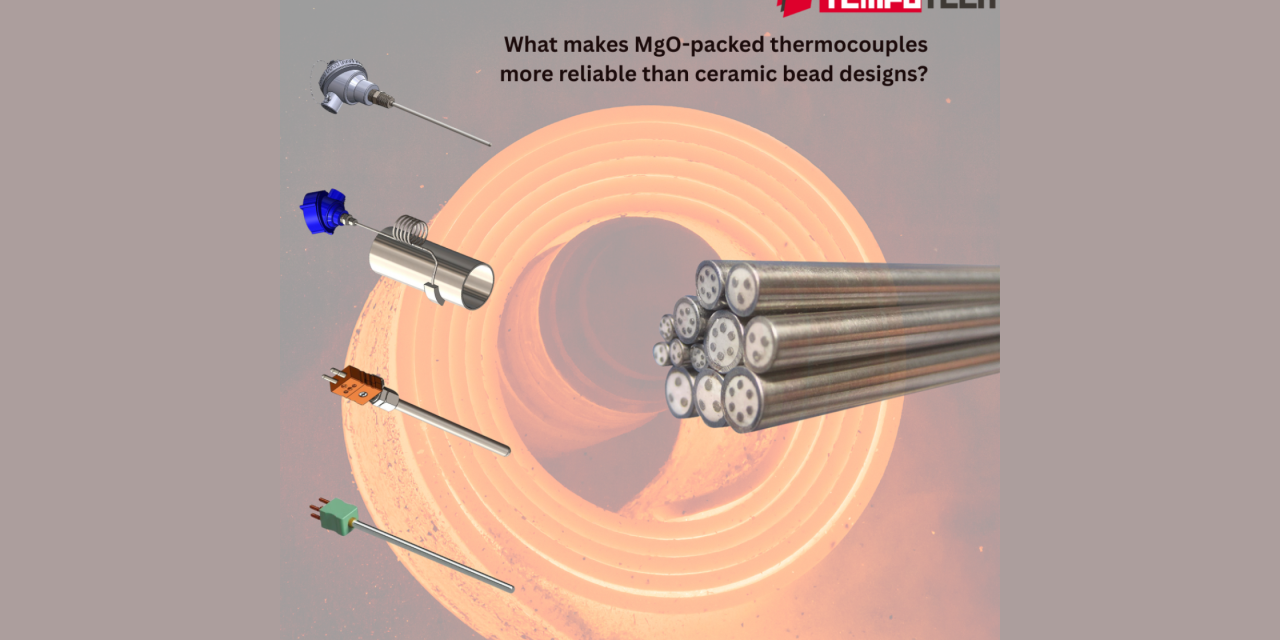

Why MgO Thermocouples Are Better Performers Than Ceramic Bead Thermocouples

MgO-packed thermocouples, also called mineral-insulated metal-sheathed (MIMS) thermocouples, are a reliable and durable choice compared to ceramic beaded thermocouples. MgO thermocouples are constructed by placing thermoelements inside a metal sheath insulated with high-purity MgO (magnesium oxide powder). The cable is then redrawn to the required size and heat-treated to normalize the metal conductors and sheath....